Description

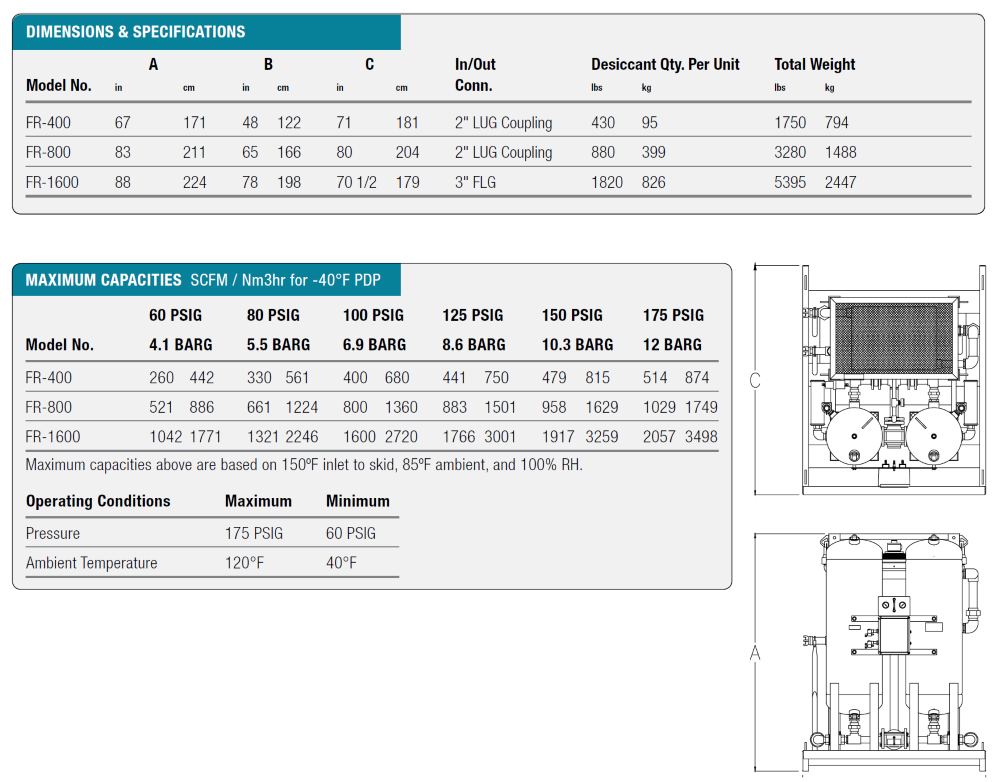

Van Air Systems FR-1600 Prep 40 compressed air dryers have been designed for the rugged demands of the rental equipment industry. Heavy duty structural steel frame work protects key components. The Prep 40 will produce compressed air with a -40°F pressure dew point, remove particulates down to 1 micron, and reduce lube oil content to .008 PPM.

These dryer skids are as close to plug-n-play as equipment gets. Just hook up compressed air hoses, supply 115V power, and the dryer is ready to begin working. For the ultimate in mobility and portability, look no further than the Van Air Prep 40 regenerative compressed air dryer system.

The Van Air Prep 40 series delivers clean, dry and cool compressed air in one integrated forklift skid package. The FR-1600 compressed air dryer package includes an aftercooler, moisture separator, pre- and after-filters, and an HL series heatless dryer. No other air dryer manufacturer offers a skid packaged regenerative compressed air dryer with an onboard aftercooler. The compete air drying package is designed for anyone who needs -40°F dry compressed air. Eliminate the use of a separate aftercooler and save time and hassle with portable air preparation packages for cool, clean and dry compressed air.

- Van Air Prep 40 FR-1600 Portable Compressed Air Air Dryer

- All-in-one portable air dryer package

- Tough enough for the rental market

- 1,600 SCFM and 150 PSIG

- -40°F dew point

- Made in USA

FEATURES

- Aftercooler

- Y Strainer

- Moisture Separator w/ drain

- Prefilter and Afterfilter

- Regulator Lubricator and (2) Relief Valves

- Pneumatic Drain Valve

- Simples installation. Just connect air lines in & out and power supply,.

- Heatless Regenerative dryer for -40°F Pressure Dew Point

- 150 PSIG maximum working pressure

- Compact profile for ease of transport

The Van Air Systems Prep 40 Air Dryer System is recommended for:

- Sandblast and painting operations that require -40°F Pressure Dew Point

- Back up air treatment if portable compressors are used when a primary compressor goes down

- Rail Yards

- Shipyards

- Rental Air / Compressor Houses

STANDARD EQUIPMENT

- Inlet Y-strainer

- Regulator - lubricator

- Trim Cooler with air motor, 15°F approach

- Bulk moisture separator with auto drain

- Coalescing pre-filter, with auto drain

- Heatless regenerative dryer

- NEMA 4X control enclosure

- Power on/off switch

- Power on light

- Purge mufflers

- Failure to switch light

- PDV-500T Drain

- Hour meter

- Tower pressure gauges

- Visual moisture indicator

- Control air filter

- Nylon control air tubing

- Open frame fork lift skid

- Four point lifting lugs

- Activated alumina desiccant

- Canadian Registration Numbers (CRN) (FD-400 & FD-800 only)

- Safety relief valves

- Purge flow gauge

- Epoxy/polyurethane paint

Literature

Video